Automated Phantom Tank

Senior Project (SJSU)

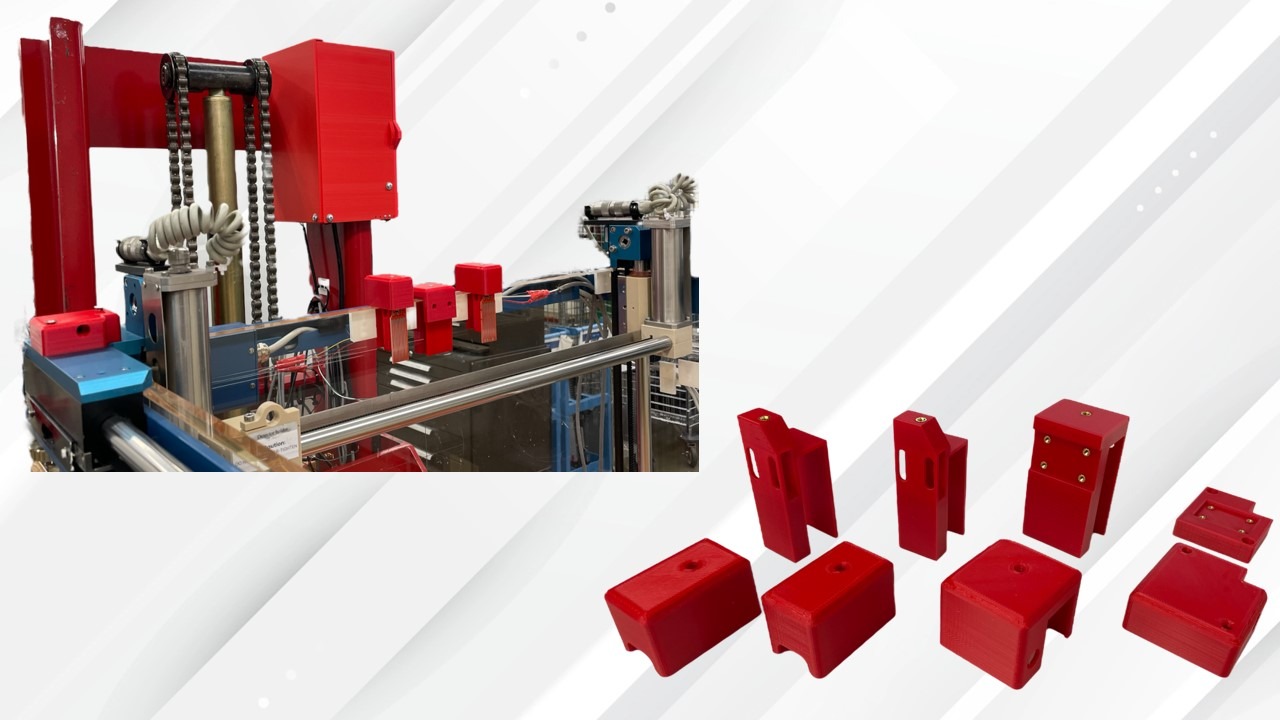

Designed and implemented a fully finished internal product for Varian. It automates their Phantom Tank, used for tuning their Radiotherapy machines. Varian implemented this system and is saving at least $150,000 annually in labor alone.

Varian is now implementing these systems in all of their factories worldwide.

The new tank reduces production time while adding precision and consistency to the tuning process.

The video below shows the tank in action.

Parts involved:

High-Torque Stepper Motors, Switch Mode PSU, Accelerometers, Ultrasonic Sensors, Hydro Sensors, Relays, and multiple Arduinos communicating with each other wirelessly.

Firmware:

To take the code to industry standards, 15+ interrupts and 5+ finite state machines have been implemented. I2C is used to route fewer wires from the user panel to the tank. SPI was used for the transceivers.

Features:

By simply pushing the corresponding button, the tank can:

- Level itself in radial and transverse planes

- Drive itself to the specified height for each test

- Fill itself to the appropriate water level

- Drain itself after testing is complete.

Gallery

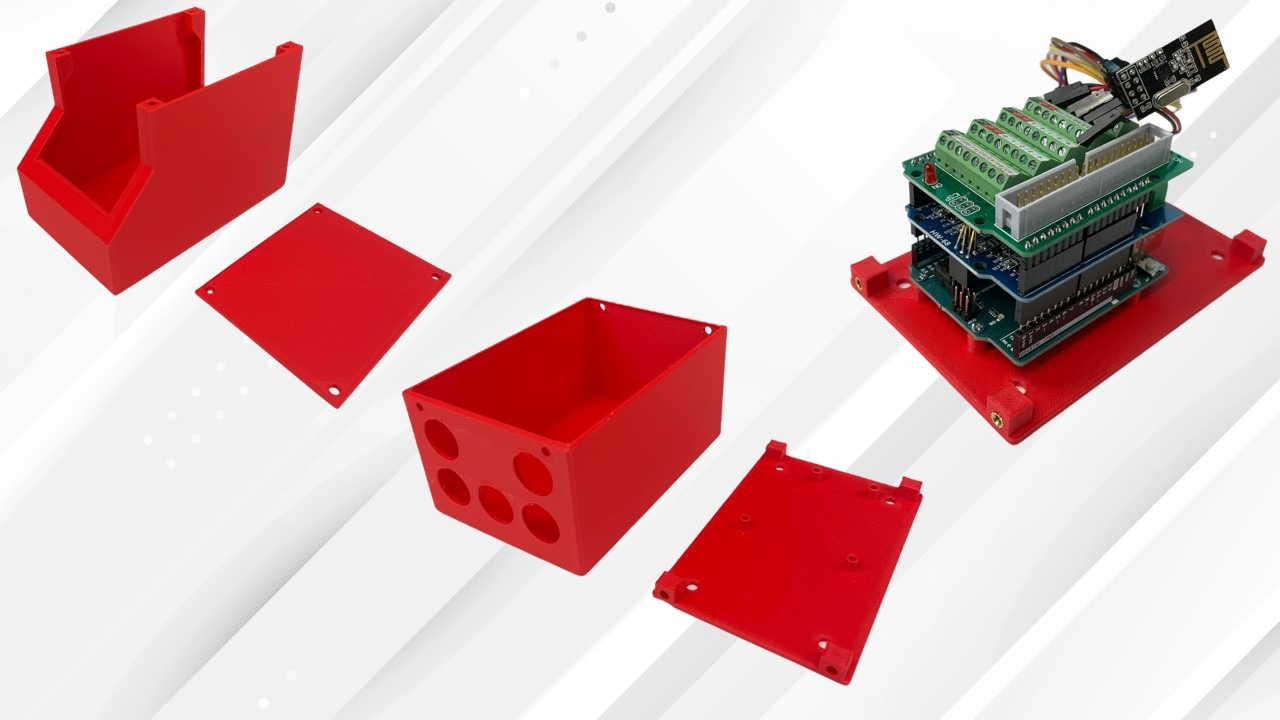

User Panel (3D-printed)

User Panel with Covers on

Manufactured Sheet Metal (designed using SolidWorks)

Motor Covers

Sensor Covers

Relay Covers

Post a comment